DM-MSD6012 aluminum foil paper protective agent

Category

Label List

- Product Description

-

Performance characteristics

MSD6012 is a kind of active silicone polymer emulsion, it has good wettability on the metal surface, smooth folding, waterproof, mildew, anti-adhesive effect, is dedicated to the tobacco industry to adapt to high-speed packaging machine (8000~12000/min) requirements of the aluminum foil surface treatment agent. The aluminum foil paper treated with it has excellent surface smoothness, greatly reducing the friction coefficient between aluminum foil composite paper and packaging equipment, greatly improving the work efficiency, and the treated aluminum foil paper has both stiffness and flexibility. Both hard and soft, soft and hard, are most suitable for embossing requirements.

Technical indicatorsAppearance

Milky White liquid

Stability

3000r/min, 15min without delamination

Solid content

20±2%

Use

For the tobacco industry aluminum foil composite paper aluminum foil surface slip treatment. It can also be compounded with water-based acrylic resins to enhance comprehensive functionality.

Usage and dosage

1. Proportion: 1 part of DM-MSD6012 water; 3~5 parts of distilled water (deionized water)

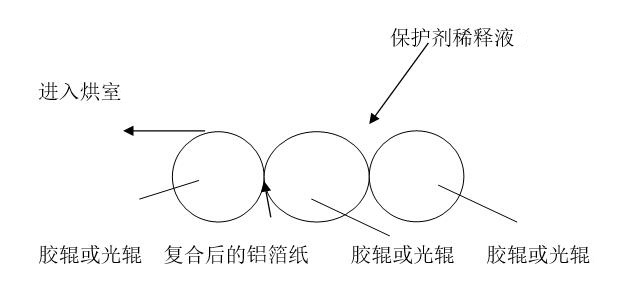

2. Process:

The DM-MSD6012 dilution solution after mixing is roller coated with a multifunctional aluminum foil laminating machine. When in use, the protective agent is pumped between the two rotating rollers with a circulating pump. The surface of the roller is adsorbed and evenly applied to the aluminum foil surface of the composite paper, and then enters the drying chamber for drying (80~120 ℃). The paper speed shall not affect the crisp loss of the aluminum foil paper. The residual moisture on the surface of the aluminum foil is dried by a fan at the end, and then the roll paper can be cut together or separately.

3. Schematic diagram of coating

Precautions

① DM-MSD6012 can not be directly mixed with alcohol, nor can it be mixed or diluted with water with high hardness and high content of inorganic salt molecules. Distilled water or softened water or boiled water should be used to mix or dilute, so as not to cause floating oil and cause unnecessary trouble. When you must add alcohol, please contact the technical department of Meister Company.

② Under normal circumstances, the DM-MSD6012 is not mixed with color paste or dye application, when the user needs to paint aluminum foil while enhancing smoothness, please contact the technical support department of Meiside Company.

③ When the DM-MSD6012 is finished in a production shift and the production is not continued immediately, the roller should be cleaned in time. Before drying, it can be wiped with a clean cloth. If it is dry, it should be wiped with a cloth soaked with gasoline or chlorofluorocarbon.

The best application of smooth coating roller elastic roller, roller coating uniformity has been proved to be better than the rigid steel roller, coating between the roller and roller to squeeze closely, to prevent uneven coating.

④ If there is not enough space for three rollers at the same time at the coating site, and the coating must be carried out with the help of a color-coated blade, please contact the technical department of Meider Company. Special tackifier can be used to ensure the uniformity of coating.

⑤ DM-MSD6012 are considered non-toxic and low-irritating materials, but it does not mean that they can be eaten. If you are not afraid of splashing into your eyes or on your skin, you can wash it with water.

Packaging, Storage and Transportation

Packing: This product is packed in 50kg,200kg barrels;

Storage: Avoid mixing with acid, alkali and salt substances during storage and transportation, and the storage period shall be subject to the second half of the year at normal temperature;

Transportation: non-toxic and non-dangerous goods shall be stored and transported.

Label List

DM-MSD6012 aluminum foil paper protective agent

Product Category

Best-selling products